Lithium-polymer

The lithium-polymer or lithium-ion-polymer technology is a succession of the base or lithium-ion technology. However, they differ from each other in structural parts related to the chemical functions and the internal structure of the cell. --> Nominal voltages / ranges

This form of technology is basically "macromolecule cells" , a now more familiar term for this is "polymer".

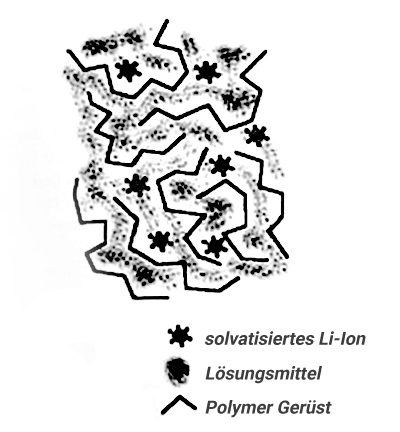

The main difference - or in other words the functional difference of a lithium-polymer cell - comes from the gel-like electrolyte, there are now both gel and non-gel electrolytes on a polymer basis.

The "polymer electrolyte" consists of a polymeric framework. In this class of membranes, due to the polymer structure, there are practically no continuous paths for the electrolyte solution in which dendrites can form.

(Dentrites: Lithium deposits that can cause local short circuits and contribute to an increase in self-discharge.

The polymer structure

The polymer structure is used in the cathode as well as in the electrolyte, the aim is to gain mechanical as well as electrochemical stability. The polymer cells are mainly used in the high current cells, because of the high discharge rates the "polymer structure" was developed. Simply put, this leads to higher conductivity and significantly increases the cell strength. In terms of safety, this technology also offers increasingly advanced safety features; the separator, for example, is embedded in a chemically more stable way and is more "shock-resistant" than electrolytes with a non-polymer base.

Cell chemistry based on LiCoO2:

Lithium Cobalt(III) Oxide (LiCoO2), or LCO for short, is a chemical compound of lithium, cobalt and oxygen and is used as the positive electrode material in lithium cobalt dioxide accumulators. (In our cell variants designed as a lithium-polymer accumulator). Depending on the application and the specified performance expectations of the cell, the appropriate active material or mixture is selected. Our lithium-polymer high-performance cells are currently based on LiCoO2. Here, too, there are a number of possibilities to influence one property of the cell at a time. On the basis of the mixture, this is achieved with the materials and additives used in the electrode substrates (anode/cathode), as well as the electrolyte and the separator. (CAS: 12190-79-3) (EC NO / EC Index: 235-362-0)

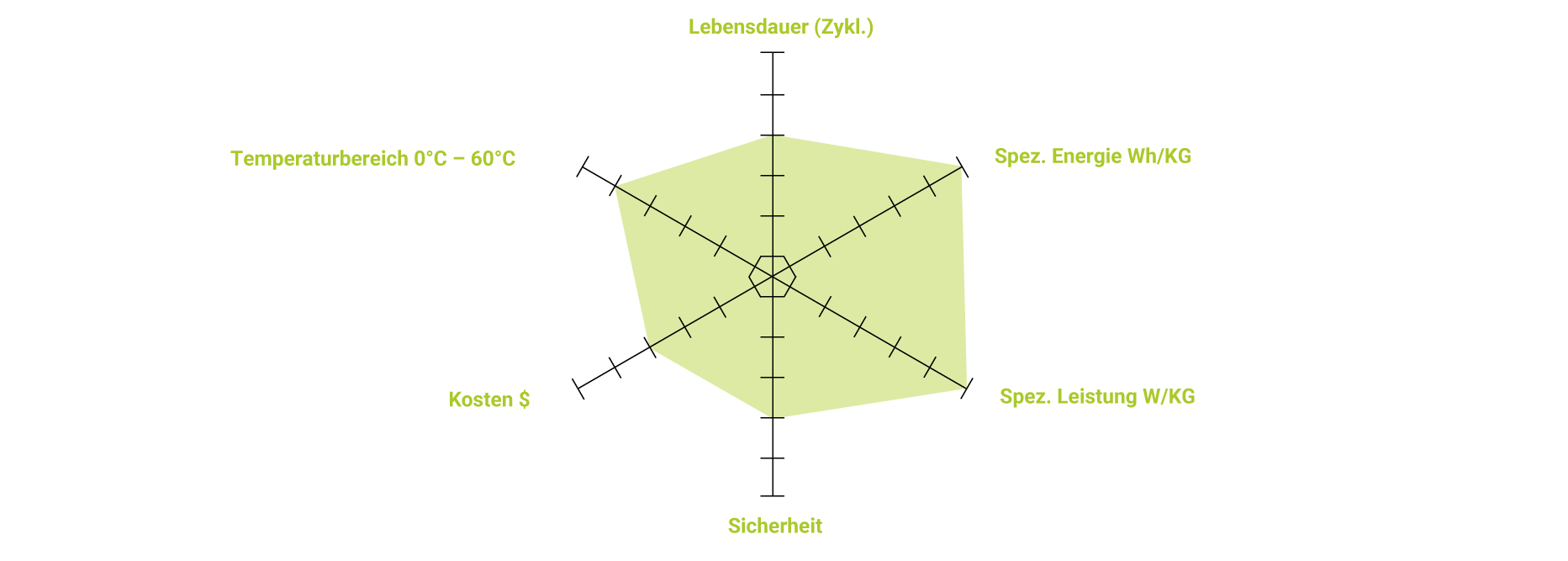

Service life

In order to specify the service life, the prerequisite of the fit to the application must be taken into account. To then evaluate the expected lifetime, we need to specify the EoL (End of Life). It is a good idea to assume an EoL at 80% remaining capacity, but this is a possibility and by no means a must. It should be taken into account that we can define the EoL both from the application or project specifications and from an existing cell where we calculate with the cell data as given values.

The service life then refers to the time between the delivery date and the defined criteria for the EoL, at which the ageing that has occurred, the degradation of the cell, falls below the set limit values. A general definition cannot be made here as there are no generally valid criteria.

It must also be taken into account that the cells age even when not in use; this ageing is defined as "shelf life". The shelf-life value is again dependent on the battery parameters. Irrespective of the application, the shelf life value can be positively counteracted in production and in terms of delivery condition if, for example, the cells are provided with a longer storage time before initial use.

Specific energy Wh/KG

The energy density (gravimetric watt-hour per KG) indicates the amount of energy that can be stored on a specific weight. The amount of energy watt-hour, is calculated from the capacity in Ah (ampere hours) x the voltage V (volts)=XY watt-hours. The number or amount of watt-hours is then put in relation to the weight of the battery. (Wh/KG)=Specific energy density.

LiCoO2 technology usually has a very high value in terms of energy density, depending on the design of the mixture and the additives.

Specific power W/KG

The specific power, also called power density, (Watt, or Ampere), i.e. the possible current output of the accumulator is nominally indicated with a C-value. The C-rate refers to the nominal capacity of the accumulator and serves as a factor for calculating the possible current output. For a cell with 5000mAh capacity and a continuous discharge rate of 25C, the possible discharge current is 125A.

Attention: The C-rate is always a theoretical discharge value, which can be reached under optimal conditions (state of charge, age, operating and ambient temperature, etc.). For applications without an active or passive cooling system, we recommend planning a power reserve of 15-20%.

The LiCoO2 Technology enables one of the highest specific outputs in series production according to the current state of the art, if the cost/benefit factor is also taken into account.

Discharge rates of up to 100C or more are possible, but it must always be taken into account that other specific performance values of the cell can be influenced and possibly worsened by this.

Safety

The safety issue is still one of the main factors of lithium-ion technology in general. While LifePO4 technology, for example, can almost rule out thermal runaway, the LiCoO2 variant requires further safety barriers or measures to ensure safe operation and storage.

Both mechanical and electrical safety must be taken into account. Mechanical damage can lead to internal short circuits, leakage of the electrolyte, etc., so it is imperative to ensure that the cell remains hermetically sealed and undamaged, regardless of the design.

Costs

Lithium batteries and technologies have been showing a degression in terms of costs for years. Nevertheless, the question of costs must be considered individually, but generally the criterion of costs per watt-hour is used.

In addition to the costs of the mixture, the type of construction, the raw material prices and the quantity of cells required or the size of the production batch also play an important role.

Temperature range

The lithium accumulators or technologies behave very differently depending on the structural composition and choice of active materials, as well as the design of the electrodes (cathode / anode).

The consideration of the temperature curve, thought from the perspective of the application and its charging and discharging needs are the central factors that must be taken into account when choosing the right technology.

With different additives and the appropriate choice of foils, we can decisively influence the temperature properties of our cells.

Design & Engineering

Benefit from more than 5 years of experience, our portfolio includes smallest projects up to complex large-scale projects for industry and commerce. From the single cell to the complete battery pack. We are happy to design your solution.

Technology

The technology is the basis of all functions and is therefore crucial for the success of the application and for the complete life cycle. With the choice of technology, we lay the foundation for performance and service life.

Certification

In order to be able to effectively prove the properties and performance characteristics of your product to your customers through recognised labels, we offer a comprehensive service for CE, RoHS, EMC, Battery Directive, UN38.3, DG certification, MSDS etc..

Environment & Sustainability

Our efforts with regard to sustainability go beyond the minimum requirements ofthe obligation to inform and take back our products. Thus, we focus on the entire life cycle of our products.